EPS (Expanded Polystyrene) is usually not the first thing that comes to mind when the social buzz words green, environmentally friendly and recycled are being used. However, foam is one of the most earth friendly packaging materials available on the market. Armstrong Brands, Inc. molded foam packaging is known for its toughness, versatility and water resistance, but the low impact on the environment and non-toxic properties are equally as significant.

EPS is an inert material, which simply means that when it decomposes or breaks down no chemicals or gases are released into your breathing space. In fact, expanded polystyrene is over 90% air. It is so safe that it is approved for food packaging worldwide and foam containers are often used to transport vital organs for transplant patients. Armstrong Brands, Inc. manufactures thousands of reusable and safe containers for use in the medical, pharmaceutical and food industries and without cutting down one single tree.

By its nature, foam is easily molded and sculpted for many purposes allowing quick and cost efficient manufacturing. Innovations and technological advances in manufacturing have increased production capacity while decreasing byproducts and energy consumption. In fact, in order to replace the current EPS packaging products with traditional cardboard, paper, wood, etc., manufacturing energy consumption would more than double.

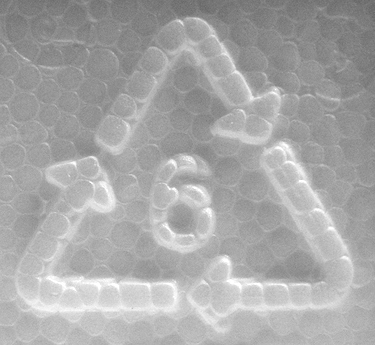

100% of the foam products manufactured at Armstrong Brands, Inc. can be recycled, reused or reclaimed. There are many different processes that can be used to recycle or reclaim the foam material. Scrap foam and unused foam can be shredded and mixed in with virgin material to be re-molded into a new finished product. Truckloads of foam can be compacted and sent to specialty plants that can re-use the foam for corner protectors on frames and other uses. In some cases the foam is completely reprocessed to make new items such as plastic hangers, cd cases and even lawn furniture. As technology advances the future definitely holds many more uses for recycled and reprocessed foam.

Most importantly, think before you throw. Armstrong Brands, Inc. is dedicated to manufacturing high quality and cost effective materials to be utilized in all arenas of business and are equally diligent in finding ways to reclaim used foam. We make products designed to be reused or recycled. If there is not a recycling center in your area we may be able to help you create a program within your company or organization. The choice ultimately belongs to all of us to utilize the options before us, and turn a good thing like foam into a great solution.

Fortunately, we live in a global environment that understands we have the power and responsibility to positively impact our planet. Armstrong Brands, Inc. shares this accountability and fervently explores new processes and innovations that will expand foam recycling and protect our shared environment. First and foremost we must all make an effort to recycle as much as possible. Even though most curbside city recycling doesn’t pick up foam there are recycling centers all across the nations. To find a foam recycling center in your area please visit: epsindustry.org or contact us.